Air Casters inflate with compressed air → create a controlled air cushion → lift the equipment → allow friction-free movement. This technology offers a modern alternative to traditional solutions like a heavy duty hydraulic lift or systems relying on large heavy duty casters.

Step-by-step process:

Compressed air fills the airbag

Airbag expands and forms a thin air film

Load lifts slightly above the floor

Friction drops to nearly zero

Operators move the load effortlessly

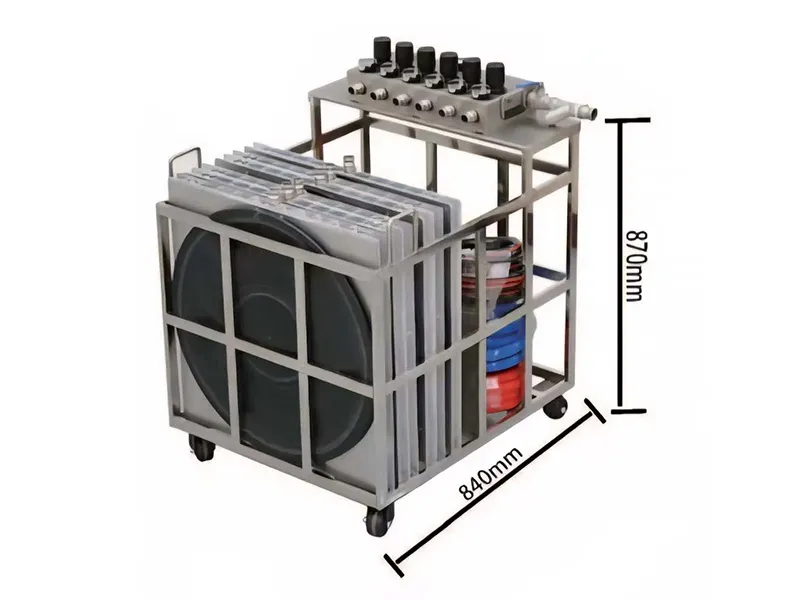

(Use the infographic you generated here.)

Even multi-ton equipment can be moved by one operator, reducing labor requirements and improving safety, offering an alternative to traditional solutions like a heavy duty air hydraulic jack.

No wheels, no rollers, no scratches. Ideal for epoxy floors, cleanrooms, and high-value equipment.

Move equipment forward, backward, or sideways with millimeter-level positioning.

No expensive cranes, forklifts, or large moving teams needed.

Air Casters require no turning radius, perfect for narrow aisles or crowded production lines where even a heavy duty low profile floor jack may not be maneuverable.

Load weight (tons)

Center of gravity

Equipment footprint

Floor type (epoxy, concrete, metal plate)

Movement distance

Required precision

We offer customized Air Caster kits tailored to your equipment and environment. This ensures a solution that perfectly matches your specific needs, much like selecting the right heavy duty air hydraulic jack or heavy duty low profile floor jack for a particular lifting task.

Air Casters win for safety, precision, and high-capacity movement.

| Feature | Air Casters | Forklifts | Rollers |

| Floor Damage | None | High | Medium |

| Movement Type | 360° | Forward/Reverse | Limited |

| Noise Level | Very Low | High | Medium |

| Required Manpower | 1 person | Multiple | Multiple |

| Cost | Low | Medium–High | Low |

| Load Capacity | Very High | Medium | Medium |